How to Identify High-Quality Marble Blocks: A Guide for Importers

For marble importers, sourcing high-quality marble blocks is crucial to maintaining customer satisfaction, reducing waste, and maximizing profits. But with so many options available, how can you ensure you’re selecting the best? In this guide, we’ll explore the key factors to consider when assessing marble blocks, from quarry selection to surface quality and structural integrity.

1. Source Matters: Choose a Reputable Quarry Owner

The origin of the marble plays a significant role in its quality. Different regions produce distinct types of marble with unique characteristics. Some of the most famous marble-producing countries include:

Iran – Famous for high density, uniform texture, and elegant veining

Italy – Home to premium Carrara and Calacatta marble

Turkey – Known for high-quality white and beige marbles

India – Offers a variety of colors and textures

Brazil – Produces exotic and vibrant marble varieties

Working with a trusted quarry owner ensures consistency in supply and quality. Look for suppliers with good industry reputation, certifications, and strong quality control practices.

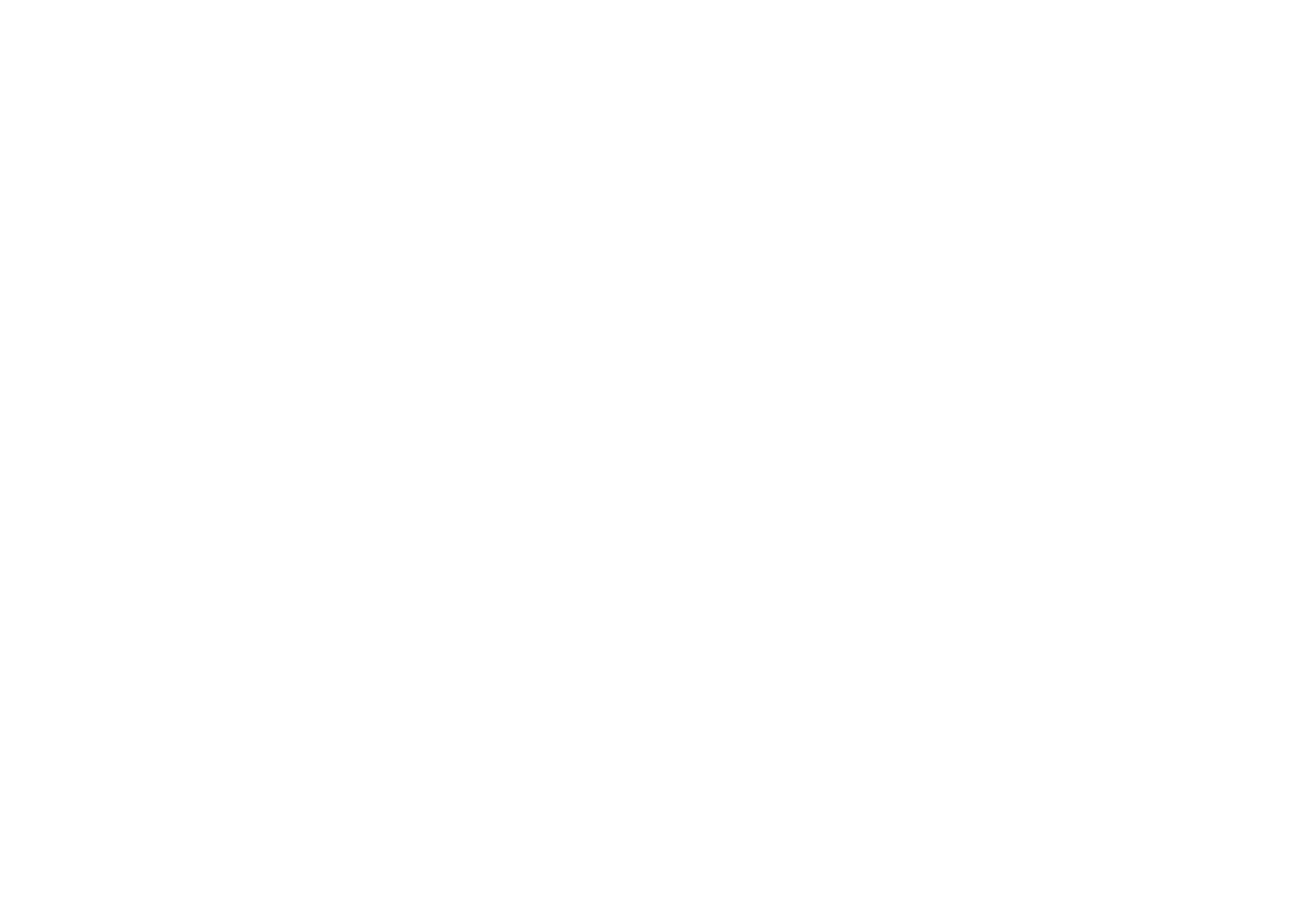

2. Check the Color Consistency & Veining Patterns

Marble’s natural beauty lies in its color variations and veining, but inconsistencies can impact its marketability. When selecting blocks:

✔ Uniformity: Choose blocks with a consistent base color and well-distributed veining.

✔ Veining Patterns: Natural veins should be smooth, flowing, and not abrupt or chaotic.

✔ No Undesirable Discoloration: Avoid blocks with excessive stains, dark patches, or unexpected color shifts unless they are part of the stone’s natural appeal.

Some high-end natural stone , like Saturn or leopard, have bold veining that enhances their value, while others, like Cream , have softer, more subtle patterns.

3. Surface & Texture Quality: Look for a Smooth Finish

A high-quality marble block should have a smooth and clean surface. To check for surface quality:

✔ No Visible Cracks or Fissures: Natural cracks may weaken the structure and lead to breakage during cutting.

✔ Fine Grain Structure: A compact, fine-grained texture usually indicates superior quality.

✔ Low Porosity: Less porous marble absorbs less water and is more durable.

Conduct a scratch test using a metal object—high-quality marble should resist deep scratches.

4. Structural Integrity: Avoid Internal Defects

Not all defects are visible on the surface. Some internal flaws can weaken the stone and cause problems later. To assess structural integrity:

✔ Tap Test: Lightly tap the block with a hammer—hollow sounds may indicate internal cracks.

✔ Ultrasonic Testing: Advanced buyers use ultrasonic tools to detect hidden fractures.

✔ Consistent Density: Blocks should feel solid and heavy, without weak spots.

A well-structured block ensures efficient cutting and polishing, reducing material waste.

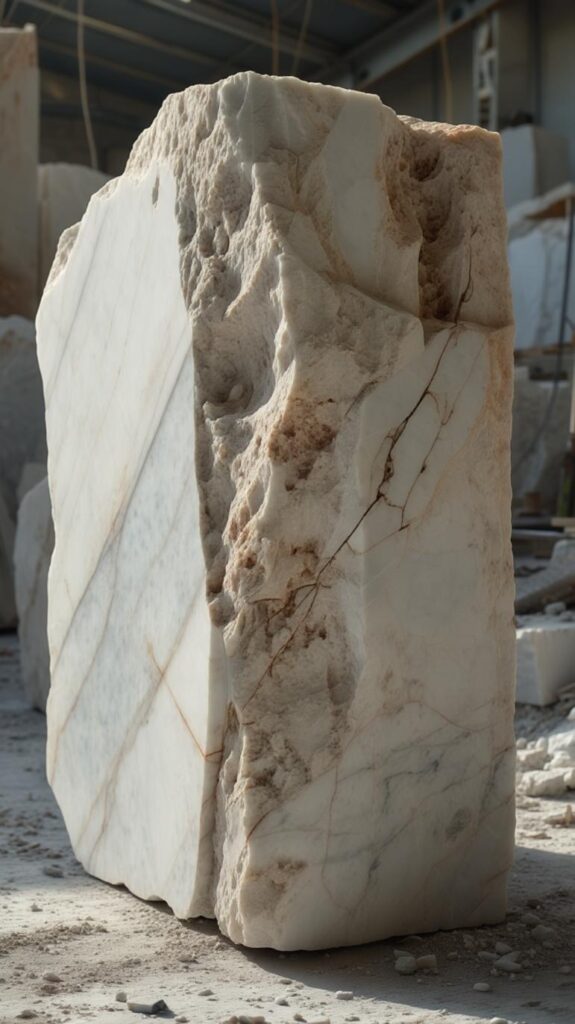

5. Moisture Content & Water Absorption Rate

Water absorption affects the durability of marble. High-quality marble should have a low water absorption rate to prevent staining and damage. To check:

✔ Conduct a Water Drop Test: Place a few drops of water on the surface if the stone absorbs it quickly, it may have high porosity.

✔ Check Laboratory Test Reports: Many quarry owners provide technical specifications, including porosity and absorption rates.

Denser marbles like Makrana White or Italian Statuario tend to have lower porosity, making them more durable.

7. Testing & Certification: Verify the Quality

To guarantee you’re buying premium marble, always request test reports and certifications from the quarry owner. Some key tests include:

✔ Compressive Strength Test – Measures how much pressure the marble can withstand.

✔ Flexural Strength Test – Assesses its ability to resist bending or cracking.

✔ Water Absorption Test – Determines its porosity level.

Certifications from reputable laboratories ensure you’re investing in a reliable and durable product.

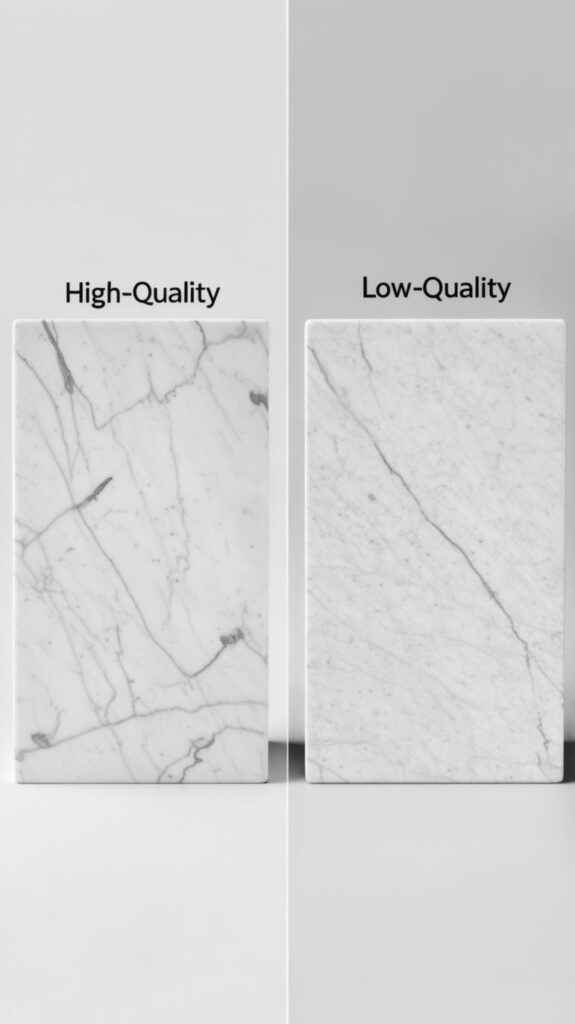

6. Block Size & Cutting Yield

Marble blocks are typically sold by weight or cubic meter, but not all blocks yield the same usable material. When choosing blocks:

✔ Look for Optimal Size & Shape: Larger, well-cut blocks reduce wastage during processing.

✔ Avoid Excessive Irregularities: Odd-shaped blocks may result in higher cutting losses.

✔ Confirm Slab Yield with the Quarry Owner: A good supplier can estimate how many slabs you’ll get from each block.

High-quality blocks maximize profitability by reducing waste and increasing usable slabs.

Final Thoughts: Making the Right Choice

Importing high-quality marble blocks requires careful selection, from choosing the right quarry owner to checking structural integrity and surface quality. By following these key criteria, you can ensure that you’re sourcing the best marble for your business reducing waste, increasing profit margins, and delivering superior products to your clients.

Looking for premium marble blocks from trusted quarry owners? Contact IRS today to explore our top quality selection!